NEXT-GEN FIRE RETARDANTS FOR EXTRUSION

Safe, toxic-free and halogen-free extrusion flame retardants passing toughest fire standards

Next-Gen GERPHOS flame retardants for extrusion

Extrusion stands as one of the stalwarts in the world of manufacturing, a process that transforms raw materials into consistent, high-quality profiles. Whether it’s creating hollow sections for pipes, designing intricate window frames, or producing long lengths of plastic sheets, extrusion plays an instrumental role. This method heats a material until it’s malleable and then forces it through a die, resulting in a continuous profile that matches the die’s shape. The applications are vast, spanning across industries like construction, automotive, electronics, and more. Given the extensive use of extruded products, it’s imperative that these materials are not only designed for durability and functionality but are also prepared to tackle unexpected challenges. Among these, the threat of fire is prominent. In a world where safety is paramount, integrating flame resistance within extrusion processes becomes more than a need; it’s a mandate

Next-generation GERPHOS flame retardants substantially enhance the fire resistance in extrusion applications. By incorporating GERPHOS into extruded materials and processes, the resultant products showcase diminished susceptibility to ignition and flame spread. This enhancement is crucial for sectors where extruded products are in environments with potential fire risks, ensuring they maintain structural integrity while adhering to strict fire safety standards.

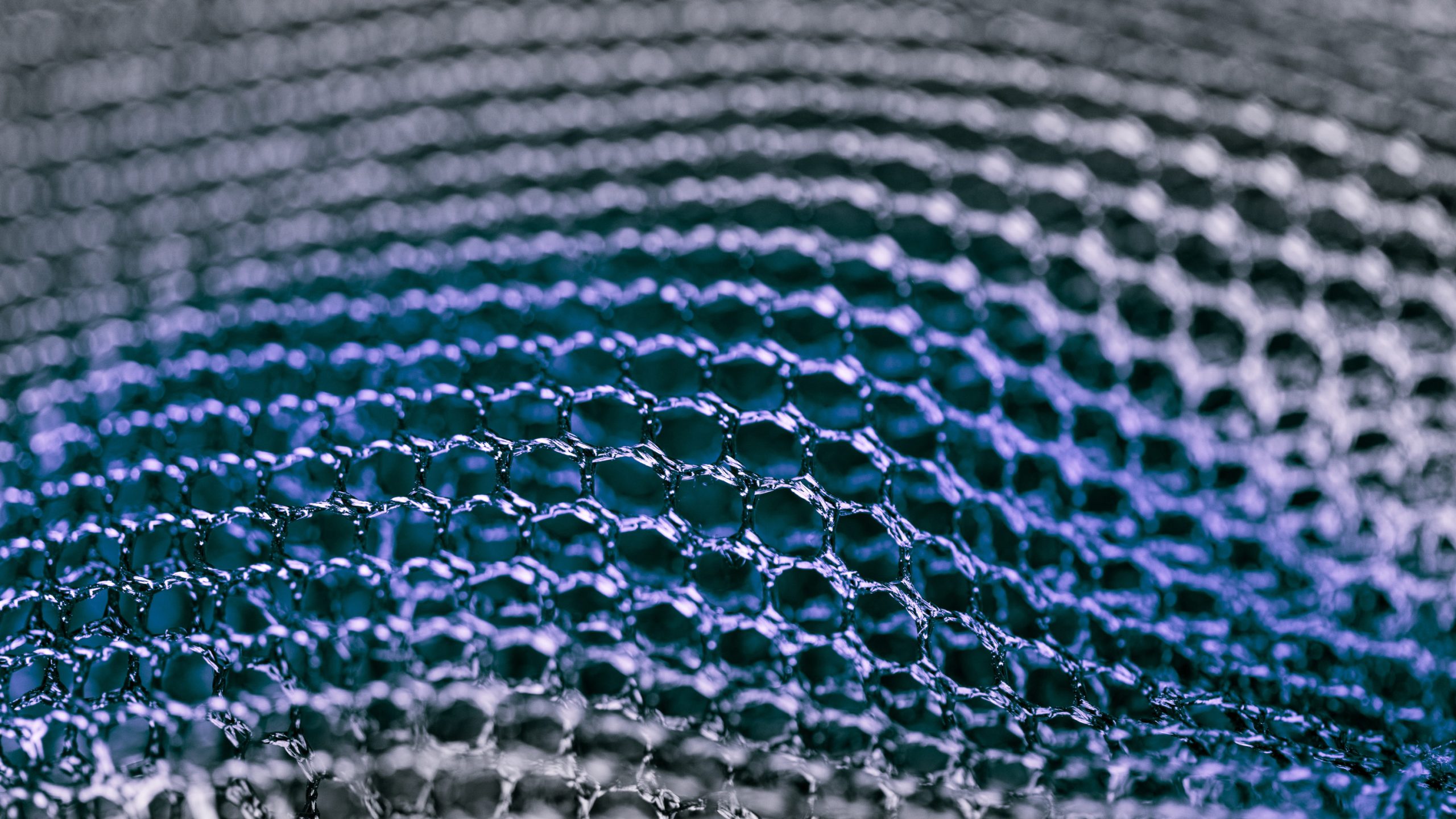

Extrusion Flame Retardants