GERPHOS® Flame Retardants for PVC Roofing Membranes

Antimony-free flame retardants for stable, compliant roofing membrane systems

Next-generation GERPHOS flame retardants PVC roofing membranes

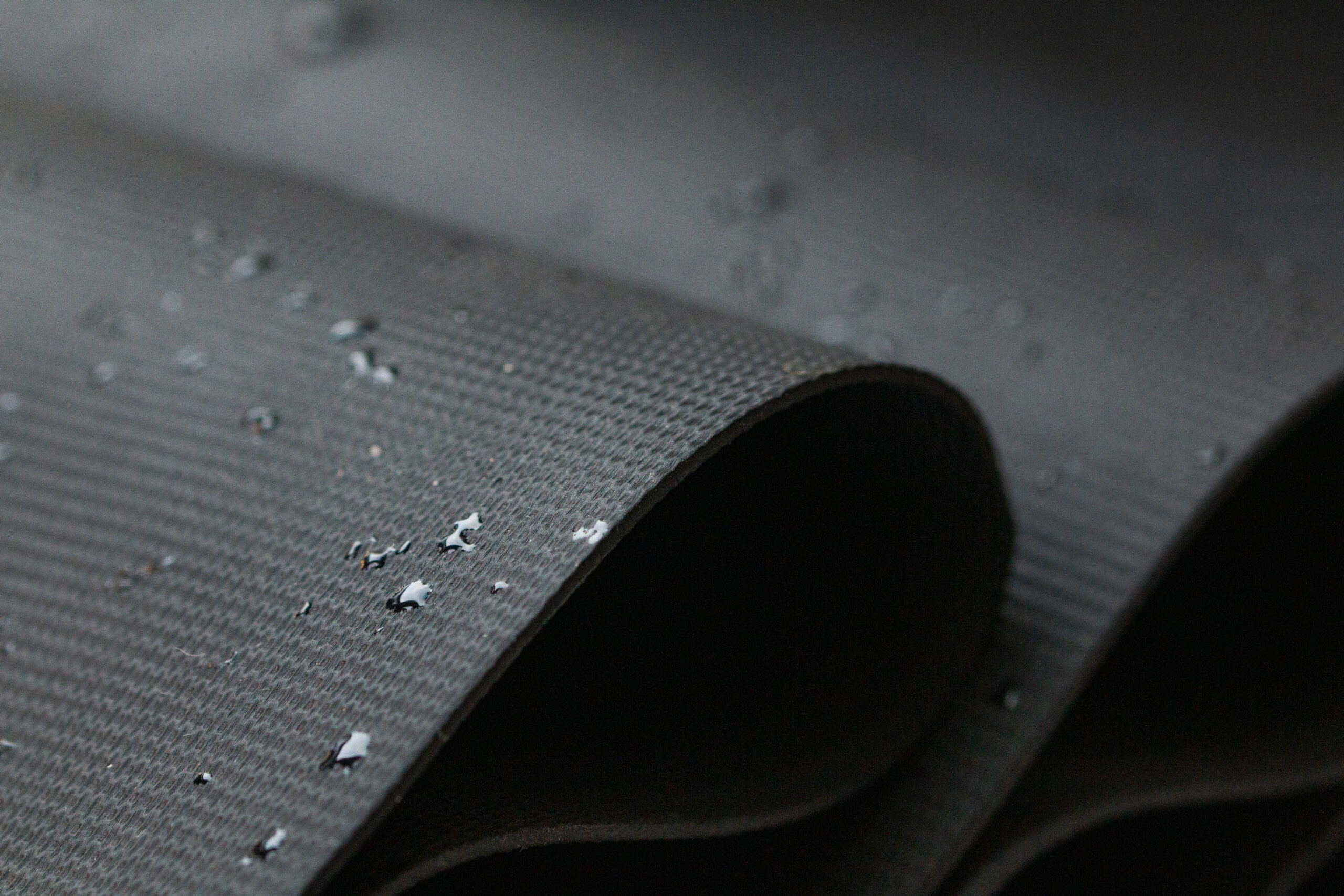

PVC roofing membranes are a global standard for flat roofs. Flame retardancy is a critical requirement, traditionally achieved with antimony trioxide (Sb₂O₃). With the ongoing antimony supply disruption and price volatility, many membrane producers are now evaluating antimony-free alternatives that keep performance and processing stable.

Roofing membranes are produced via extrusion, calendering, and spread coating at high temperatures (often above 200 °C, and higher in calendering). Flame retardants must disperse cleanly, remain thermally stable, and preserve rheology, line speed, and weldability. Long service life adds further demands: low migration, plasticizer compatibility, and resistance to UV, moisture, heat, and cold.

GERPHOS® offers a modern route to flame retardancy for roofing membranes:

- Antimony-free and halogen-free systems

- Thermal stability suited for high-temperature PVC processing

- Compatible with plasticized PVC matrices

- Designed to maintain weldability and mechanical performance

- Low migration tendency and long-term outdoor stability

- Future-proof profile with reduced regulatory exposure and supply-chain risk