Ignite Magazine

The Knowledge Platform for Next-gen Flame Retardancy

Beyond Antimony: Rethinking Flame Retardancy in PVC Roofing Membranes

PVC roofing membranes were built on antimony for decades. Today, supply disruptions and regulatory pressure are forcing a fundamental rethink of flame retardancy, exposing new risks and new opportunities for long-term resilience.

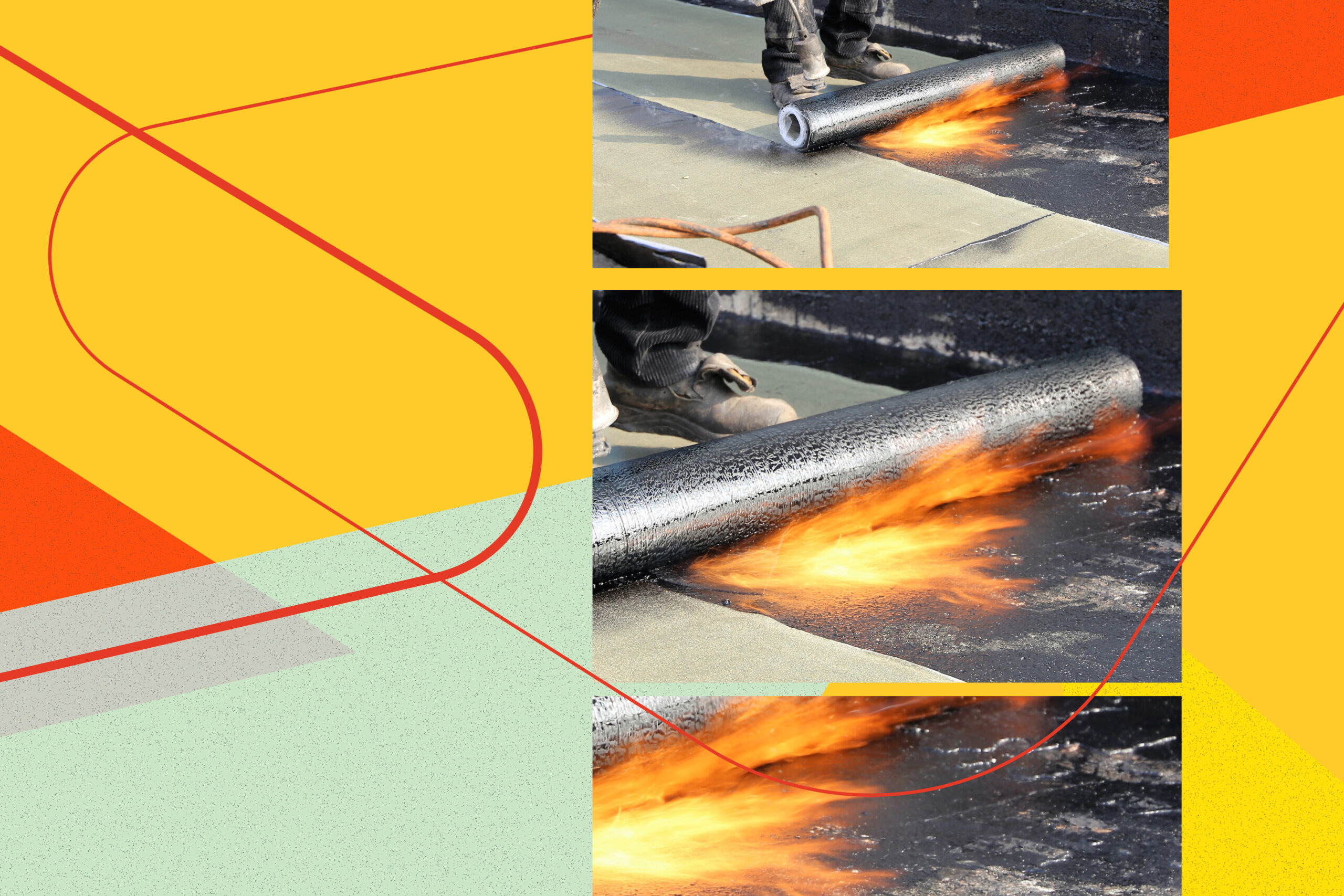

Image Credit: GULEC

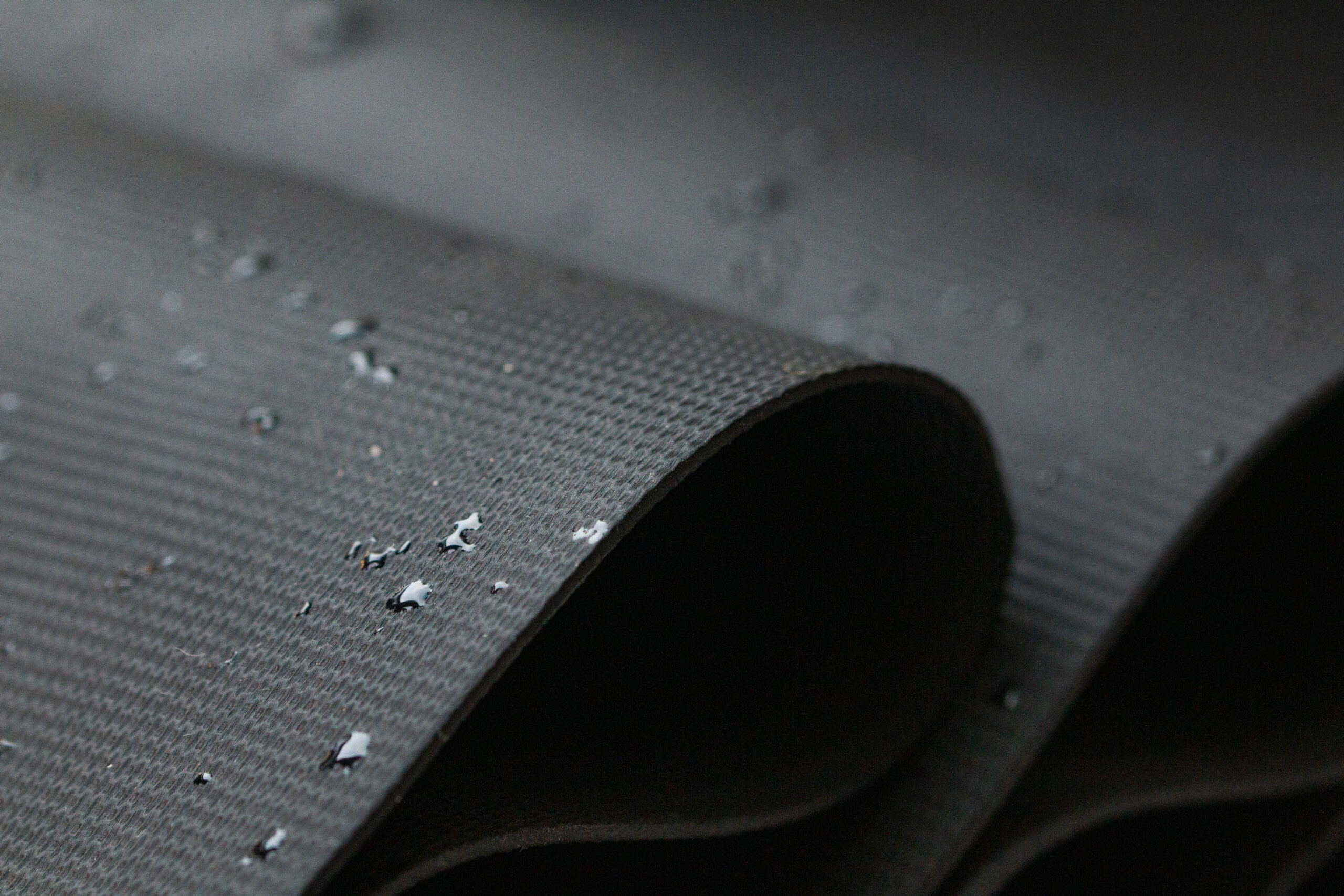

For decades, PVC roofing membranes have been among the most sought-after global standard materials for flat-roof construction. Durable, weldable, and weather-resistant, they protect buildings across climates and industries. Central to their performance is flame retardancy — historically delivered through formulations dominated by antimony trioxide (Sb₂O₃).

That foundation is now under pressure.

When a Raw Material Becomes a Strategic Risk

Since late 2024, the availability of antimony trioxide has shifted dramatically. With China as the primary producer, export restrictions have rippled through global supply chains. The consequences have been immediate: severe shortages, prices increasing by up to fivefold, and growing uncertainty in production planning.

For manufacturers of PVC roofing membranes, this is not simply a procurement issue. It exposes a more profound vulnerability: the reliance on geographically concentrated raw materials for essential construction materials.

"The antimony crisis has turned flame retardancy from a formulation choice into a strategic risk"

As a result, demand for antimony-free flame retardants and halogen-free alternatives is accelerating — not as a regulatory experiment, but as a necessity.

Flame Retardancy Under Technical Pressure

PVC roofing membranes are manufactured through extrusion, calendering, and spread-coating processes that operate well above 200 °C, with calendering lines often exceeding 260 °C. At these temperatures, flame retardants must remain thermally stable, disperse evenly, and integrate smoothly into the PVC matrix.

Any weakness becomes visible fast:

- Agglomeration during processing

- Shifts in gelation behavior or viscosity

- Reduced line speed and inconsistent membrane quality

Flame retardancy in roofing membranes is therefore not an isolated additive function — it is a core processing variable.

Weldability: Where Formulation Meets Reality

Roofing membranes rely on heat-based welding for long-term performance. Hot-air and wedge welding — and, in some cases, flame welding — operate within a narrow, sensitive window.

Additives that influence softening point or melt flow can compromise seam strength. The consequences are well understood:

- Reduced seam cohesion

- Increased embrittlement

- Higher risk of failure under thermal cycling

A flame-retardant that performs well in fire testing but disrupts weldability poses a risk where it matters most: on the roof.

Designed for Decades of Exposure

Unlike many PVC applications, roofing membranes spend their entire service life outdoors. Continuous exposure to UV radiation, moisture, heat, cold, and hydrolysis places extreme demands on material stability.

"Roofing membranes are designed for decades of exposure. Flame retardancy must be just as durable."

Flame-retardant systems must therefore:

- Exhibit low migration tendency.

- Preserve plasticizer stability

- Maintain mechanical performance across temperature extremes.

- Deliver consistent fire performance over decades.

Short-term compliance is not enough. Long-term reliability defines success.

What Modern Flame Retardants Must Deliver

The current market shift has clarified what today’s flame retardants for PVC roofing membranes must achieve:

- Compliance with standards such as EN 13501-5

- Stable fire performance without antiomony

- Thermal robustness under high-temperature processing

- High compatibility with the PVC matrix

- Minimal impact on mechanical properties and weldability

- Long-term weathering resistance

- Predictable costs and reliable supply chains

This is no longer a single-property optimization. It is a system-level challenge.

PVC Roofing Materials

Halogen-Free, Antimony-Free Systems Take Center Stage

Against this backdrop, antimony-free flame retardants are moving from alternative to strategic solution. In PVC outdoor applications, modern systems are already demonstrating that effective fire performance does not require antimony or halogenated components.

Solutions such as GERPHOS® flame-retardants are explicitly designed to meet these demands. Their role is not to replicate legacy formulations, but to enable a new balance of performance, stability, and resilience:

- No antimony trioxide and no halogenated components

- Thermal stability suited for extrusion and calendering

- Stable interaction within plasticized PVC matrices

- Reliable flame-retardant performance at typical dosages

- Long-term resistance to weathering and migration

- Future-proof regulatory profiles without hazard statements

- Zero dependency on geographically constrained raw materials

Why Long-Term Experience Matters

Developing such systems requires more than reformulation. It demands deep polymer knowledge, extensive testing, and long-term field validation.

Gulec, the developer and manufacturer of GERPHOS®, has focused exclusively on flame-retardant chemistry for decades. From the beginning, its portfolio was designed without antimony, long before today’s supply crisis made that decision strategic.

PVC is the most extensively studied polymer in Gulec’s development work, with applications spanning transportation, construction, hospitality and specialty uses. This includes experience with demanding test regimes such as long-term weathering, mechanical stress, cold resistance, and low-fogging requirements.

Looking Ahead: From Replacement to Resilience

The roofing industry is entering a new phase. Fully halogen-free and antimony-free roofing membrane systems are gaining momentum. Sustainability considerations — including recyclable PVC and circular-economy concepts — are increasingly shaping formulation strategies. Regulatory pressure continues to favor lower toxicological risk and simplified classification.

At the same time, awareness of global material dependencies is growing, extending well beyond antimony to other critical raw materials.

In this environment, co-development between roofing membrane producers and additive specialists is becoming a competitive necessity rather than an option.

Halogen-free, antimony-free flame retardant systems offer more than compliance. They offer resilience — technical, regulatory, and strategic.

And in a market defined by uncertainty, resilience may be the most valuable property of all.

Spark a Conversation

Connect with us to explore safer, smarter flame retardant strategies for your business.

Ignite Your Inbox

Be first to know about breakthroughs in flame retardancy and polymer innovation.