stay up to date

Subscribe to the Ignite Magazine Newsletter

Deciphering the flame retardant challenge — A note from the CEO

In our daily lives, the role of flame retardants in ensuring the safety of the products around us often goes unnoticed. Every item – from the upholstery in our living rooms to the walls of public spaces – has met rigorous fire safety standards to earn its place. Now more than ever, the landscape of these flame retardants is rapidly changing.

Over the past decade, many traditional flame retardants that have served us reliably are now under the microscope. Their environmental impact, potential health hazards, and compatibility with evolving fire safety standards are being scrutinized. As the world wakes up to new realities, our approach to flame retardancy needs a paradigm shift. For example, modern standards such as EN45545-2 go beyond mere flame resistance. They focus on real-life scenarios, evaluating products not just on their ability to resist flames but also on how they influence the progression of a fire.

Beyond just flame spread, concerns like smoke toxicity are becoming increasingly significant. But it’s not just the flame retardants. New resins like the HighSolid PU have emerged, necessitating industries to rethink their entire flame retardant strategy, keeping in mind challenges such as enhanced mechanical properties and resistance to water damage.

In this evolving environment, the one-size-fits-all principle of the past no longer applies.

This is where GULEC steps in.

We’re not just passive observers of these changes. Through relentless research and engineering, we’ve deepened our understanding of materials and their behavior in fire scenarios. Our dedicated team of chemists, backed by years of rigorous testing, have birthed our innovative solution: GERPHOS.

GERPHOS is not just another flame retardant. It’s our answer to today’s challenges. It replaces problematic flame retardants, supports recycling, and some versions under development even derive from organic waste. GERPHOS ensures compliance with modern fire safety standards, adapts to new resins and polymers, and meets stringent requirements like those for autoclave sterilization.

In the face of these challenges, GULEC, through GERPHOS, emphatically responds:

“Challenge accepted.”

Alper Gulec

CEO of GULEC

MORE FROM IGNITE MAGAZINE

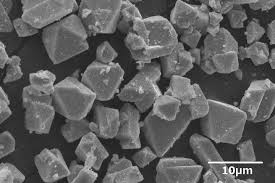

The Antimony Clock Is Ticking

Antimony prices are soaring, and availability is shrinking. If you’re still relying on ATO in your flame retardant formulations, now’s the time to rethink. In this quick update, we outline why switching to halogen-free alternatives like GERPHOS isn’t just safer—it’s smarter.

Plant-Based Leather Alternatives: Pioneering Sustainability with Advanced Flame Retardants

What if the future of fashion and upholstery is growing in a field, not a factory? How are plant-based leathers and advanced flame retardants redefining sustainability and style? Discover the innovative materials paving the way for a greener tomorrow.

eco-friendly materials, Innovation, Plant-based, Sustainability, Vegan Leather

Pioneering Fire Safety in Aviation’s Greener Era

Aviation enters a new horizon, redefining the boundaries of safety with cutting-edge flame retardant technologies. Discover how the future of flying could soar with innovative materials designed to meet the highest safety and environmental standards.

aviation, circular economy, halogen free, light weight materials, novel polymers

Ending the Antimony Era: Seven steps towards a safer, compliant and future-proof business

Antimony’s final curtain call is here, setting the stage for a new era in flame retardant applications. What lies beyond could redefine safety and sustainability for industries worldwide.

antimony trioxide, ban, carcinogenic, plasticized PVC, regulations